Hi, I’m Corinne Segura

I hold certificates in Building Biology and Healthier Materials and Sustainable Buildings, among other credentials below. I have 8 years of experience as a green building materials specifier, helping folks create healthy homes.

Have a question? Leave a comment on the related blog post and I will respond.

Latest Posts

Popular Posts

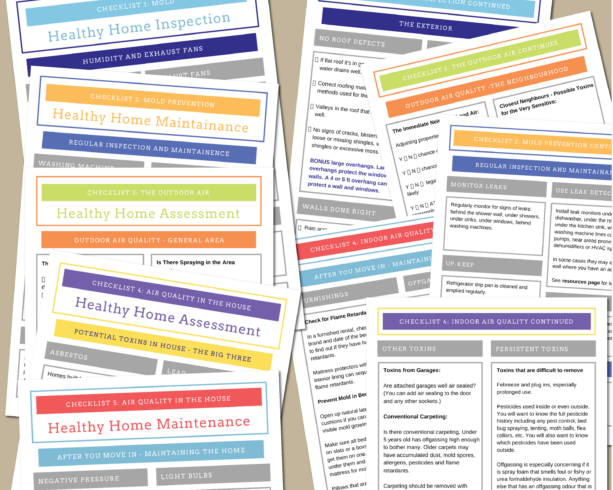

E-booklets for a healthy home

Grab the printables on Etsy!

- A Checklist for a Healthy Home

- Healthy Build Jobsite Signs

- Paint Tracker + Paint Price List

- E-Booklets on Flooring, Insulation, Paint