Hemp can be used in building homes in many ways but building with hemp is very different than building with conventional construction methods.

Hempcrete can be tamped into board-formed walls, used as premade bricks, sprayed into cavities, or formed into precast panels.

It acts as insulation and as an interior and/or exterior surface, though it is not load-bearing – you still need a wood frame.

This article will review all the ways that hemp can be used to build a healthy home and is an investigation into whether it’s mold-prone.

Before we look at the building methods closer, let’s look at what goes into hempcrete.

What is Hempcrete Made of

1. Hemp hurd

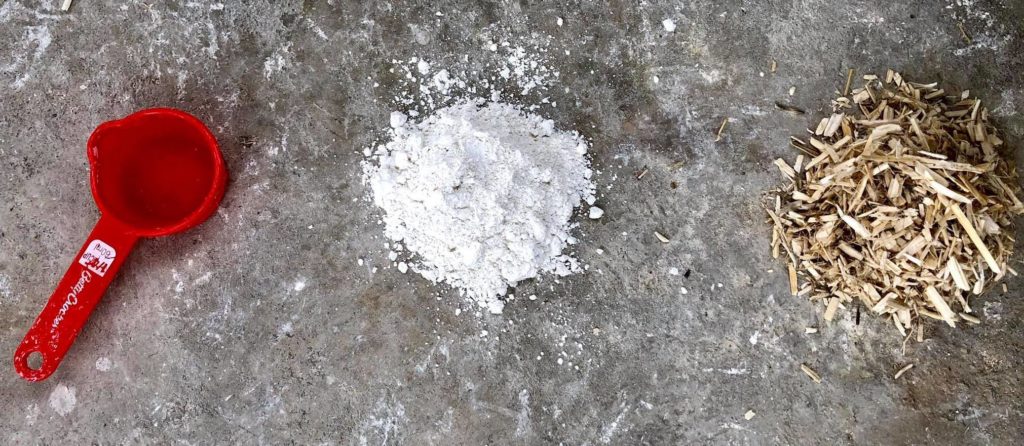

The first ingredient of hempcrete is the aggregate, called the ‘hurd’. Hurd is the woody core of the hemp plant that remains after the plant has been stripped and the fiber sold for rope or textiles.

The hurd is like the inside of a twig, after the bark has been stripped off, just less dense and with a hollow core. The woody core is dried and then chopped up; it looks a lot like wood mulch.

Hemp is an organic material – meaning, it is carbon-based, just like wood (and can be mold food, just like wood). In fact, it contains more cellulose than wood does (hemp has 65-70% cellulose, and wood has 40%).

Quality is not consistent from supplier to supplier, so make sure you are buying good quality hurd before committing to a large purchase.

A good place to buy hemp hurd in the US is through Hempitecture in Idaho.

2. Lime Binder

The lime binder contains calcium carbonate (lime) and compounds which allow it to harden – either soluble silica, alumina oxide, or ferric oxide. When a lime binder can harden with the addition of water, this is called hydraulic lime.

Hydraulic lime is readily available in the UK and France but is difficult to find in North America and often has to be imported.

There are some binders that are produced in the US. One place to buy lime binder in the US is also through Hempitecture.

Do your research on binders before choosing one. There are binders out there that have caused mold problems where there shouldn’t have been any due to added ingredients in the binder.

3. Water

When water is added to the hydraulic lime binder, it causes a chemical reaction (hot!) which makes it possible for it to harden once dried.

4. Air

It feels funny to list air as an ingredient, but it’s one of the most important parts of hempcrete!

When dried, there are many air pockets in hempcrete – both between the pieces of hemp and inside each piece of hemp.

Air is what makes hemp a good insulator (air is the most important part of any insulation) and humidity regulator.

Put them together!

When hemp hurd is mixed with the lime binder and water, it dries into a hard solid mass.

Before it dries, you sprinkle it into framed molds that surround the building’s wood framing. It is then tamped down to compress it a bit, and left to dry.

The drying time is important (between 4-8 weeks). If you don’t allow it to dry enough before removing the formwork and plastering, there could be big problems (mold, staining, crumbling).

Mixing hemp and lime together: https://www.instagram.com/p/Bsn2G21hMxn/?utm_source=ig_embed&utm_campaign=loading

Building with Hempcrete: How it is Used

Hempcrete can take the place of insulation, drywall, and siding in a new wall.

It is not a 1 to 1 replacement, though; Hempcrete can’t just be substituted for fiberglass insulation (or cellulose, etc.). Using hempcrete requires a different plan and approach compared to conventional building.

Besides being a totally different type of material and insulation, hempcrete has a different insulation value than fiberglass or cellulose, and so it will require thicker walls.

As Insulation

This is a cross-section of a hempcrete wall – the hempcrete encapsulates the wood framing.

Hempcrete’s most important function is as insulation. The amount of insulation you require will determine how thick your wall will have to be.

The insulation requirement (R-value requirement) depends on your local codes. The colder the climate, the thicker the wall will have to be.

Hempcrete’s R-Value is usually listed as ranging from 2-3 per inch. But some companies have claimed it can be as high as 4.8 per inch.

Photo courtesy of Hempitecture.

As Siding (Exterior Skin)

This is the exterior wall of a hempcrete tiny house before plastering.

The outside of hempcrete can be plastered, similar to the interior. This can create more moisture risks if not done precisely or maintained properly.

This might not be advisable in certain climates. Please find a professional to discuss what the best exterior options are for your climate.

Photo courtesy of Hempitecture.

As Interior Wall Face (Interior Skin)

This is an interior hempcrete lime-plastered wall.

Drywall is not needed when building with hempcrete. The typical interior finish is a lime render (plaster) that is applied directly to the dried hempcrete. This allows the wall to stay vapor-permeable.

Anything that you add to the wall must be vapor permeable, inside and out.

Photo courtesy of Hempitecture.

Note!

Hempcrete is not concrete. Unlike what the name suggests, hempcrete is not made from concrete and it does not contain concrete. Even though hempcrete dries and hardens, hempcrete is not structural or load-bearing – it can’t hold up the weight of the roof. It must always be used in combination with a wood frame (or other framing material).

Reasons to Consider Hempcrete

- Hemp has a unique cellular structure that allows it to absorb and adsorb water better than other plant-based fibers. This gives it an edge in moisture management over other plant-based materials.

- The use of a lime binder makes glues and other high-VOC materials unnecessary for the wall components.

- It can help with maintaining healthy indoor air quality.

- It is a fast-growing crop, so multiple harvests can be grown in one year (it is a weed, after all).

- Hempcrete generally has very good (but not excellent) insulation value.

- It is very fire-resistant.

- We know all of the ingredients in it.

- It is vapor permeable, i.e. “breathable”- if moisture gets in, it can get out.

- It is carbon dioxide sequestering.

Building with Hempcrete, Various Forms

1. Poured, or Formed Hempcrete

With formed (or poured) hempcrete walls, the finished walls are hardened hempcrete usually plastered with a lime render.

How it works

The hemp, lime binder, and water are mixed together on-site.

Temporary wood framing aka formwork (similar to when concrete is poured) is placed surrounding the structural wood frame.

The hempcrete mix is then “poured” into place inside the wood forms and then tamped down to create a thick wall. The wood forms are left there for several weeks until the hempcrete is dried.

Hempcrete creates a solid wall. There is no need for an interior wallboard, like drywall, just a nice lime plaster.

The thickness of the wall will depend on how much insulation is required by code in your location, or how much insulation you want.

Depending on location, the exterior can also just be plastered, but this should be discussed with a building science-literate professional who is familiar with your climate zone.

Photo of hemp in exterior forms: https://www.instagram.com/p/Bsa_xkVjMMi/?utm_source=ig_embed&utm_campaign=loading

Benefits of a solid hempcrete wall

- A good amount of thermal mass (heavy, thick walls) makes temperatures and humidity more even.

- Using a single material means no seams and gaps like in traditional, wood-framed houses.

- A homogeneous material makes moisture and temp management more consistent.

- A heavyweight, formable material means less need for taping or specific air-sealing layers.

- Building with a homogeneous material means there’s no abrupt shift in temperatures (i.e. at the sheathing), minimizing the chance of condensation.

- Consistent vapor openness due to single material (hempcrete) makes it easier for the wall to “breathe” and dry.

- Hempcrete works with moisture, humidity, and temperature like an experienced dance partner; conventional construction relies on keeping them away by using increasingly complex layers of barriers, insulation, boards, and tapes.

Drawbacks of a solid hempcrete wall

- It could give you false reassurance – it still requires extensive planning and precision to avoid mold.

- If not planned, mixed, and detailed correctly, it can become moldy.

- The lime dust can be hazardous to breathe in and for the skin.

- Using a framing material (i.e. wood) is still necessary.

- There are many unknowns about how it will perform in US climates.

- Contractors and laborers may be inexperienced with hempcrete.

- You will be an “early adopter”.

2. Pre-Cast Hempcrete Blocks

In order to make hempcrete thick to have enough insulation value, you can use precast hempcrete blocks on one side of the exterior wall.

The opposite side will be framed with temporary forms and be poured with hempcrete to fill the cavities and encapsulate the wood framing.

Hempcrete blocks are not load-bearing, so they will still need to be used with a wood or composite frame.

There is one company in Canada that is making a load-bearing block. They have not responded to my request for more information about the block. Their block is not approved for load-bearing use in the US at the time of writing.

Components

Most hempcrete blocks have the same ingredients as poured walls – hemp hurd, lime binder, and water.

However, there are some that have different binders, or use a finer ground hemp, and these can cause problems.

Always make sure you know what is in the block before committing to anything.

Like in the picture below, the hempcrete blocks will be placed on one side of the wood-framed wall.

A build with hemp blocks in progress: https://www.instagram.com/p/B3WirPkntVr/?utm_source=ig_embed&utm_campaign=loading

Benefits of using hempcrete block

Same as benefits for poured hempcrete, plus:

- They are pre-dried, so you can begin applying interior plaster weeks earlier than with poured hempcrete.

- Faster install time.

Drawbacks of hempcrete blocks

Same as poured hempcrete, plus:

- The cost is higher due to the labor required to cast and dry the blocks off-site.

A layer of hemp blocks complete: https://www.instagram.com/p/B3pkZnKn8uy/?utm_source=ig_embed&utm_campaign=loading

3. Sprayed-In Hempcrete

This type of hempcrete is mixed on-site, like poured hempcrete, but applied by spraying rather pouring into a form. It’s a similar process to wet-applied dense-packed cellulose or spray foam.

There must be a surface to spray against, like a hempcrete block layer or plywood.

This is a video of the whole preparation and spraying process.

Components

Same as in poured hempcrete: hemp hurd, lime binder, water.

How it works

Mixed on-site, like poured hempcrete, but applied by spraying vertically rather than pouring into a form.

According to Alex Sparrow, who owns UK Hempcrete and is the author of The Hempcrete Book, in the UK it is common to use sprayed hempcrete when renovating old stone houses. The stones have uneven surfaces and spraying allows the hempcrete to fill in the gaps and valleys.

Spraying in hempcrete: https://www.instagram.com/p/Bz_LQRRBYW7/?utm_source=ig_embed&utm_campaign=loading

Benefits of sprayed-in hempcrete

Same as poured-in hempcrete.

Drawbacks of using sprayed-in hempcrete

Same as poured concrete, plus the possible compression of the hempcrete, resulting in lower insulation values.

4. Hempcrete Prefab Panels

Some companies are beginning to produce prefab wood frame hempcrete panels. These panels combine structural wood framing with hempcrete.

Components

The ingredients in prefab panels are usually the same as hempcrete. But, like blocks, it could vary from company to company, so make sure to find out what the binder is before committing to anything.

How it works

The panels are framed with wood. They are sometimes referred to as “cassettes”. When using prefab panels, the wood framing is not encapsulated with hempcrete.

Panels will require more care for air sealing, etc. due to the wood joints. There is also more potential for thermal bridging and condensation.

Uses for prefab hempcrete panels would be similar to any prefab panel. Wall sections are made off-site and transported to the lot for installation. They could be used in place of hempcrete blocks, with poured or sprayed hempcrete on the opposite side.

A video showing hemp precast panels: https://www.instagram.com/p/Bz8amlcBfr-/?utm_source=ig_embed&utm_campaign=loading

Benefits of using prefab hempcrete panels

- Possible faster install time.

- Faster dry time.

- Less on-site prep.

Drawbacks of using prefab panels

- More detailing, similar to a traditional construction wall, because wood frame is not encapsulated in hempcrete.

- More expensive.

- Less oversight for how the wall is being made.

- More potential for problems with the wood.

- It makes interior finishes more tricky (lime plaster over studs?).

Precast panels: https://www.instagram.com/p/ttjdPmhKt4/?utm_source=ig_embed&utm_campaign=loading

5. Hemp Insulation Batts

Hemp insulation is not hempcrete but I thought I would briefly mention it here. It is not mixed with a lime binder that encapsulates the hemp hurd and hardens it.

It is hemp fibers, usually with some synthetic fibers mixed in, made into batts, and used in walls just like fiberglass, mineral wool, and other batt insulation types.

My post on insulation mentions this in more detail.

Is Hempcrete Mold Resistant?

Plain hemp can grow mold in the right conditions, but hempcrete is a little different.

Hemp–lime mixes can go moldy if it 1) absorbs water for prolonged periods of time in moist conditions, 2) does not have adequate ventilation inside, or 3) has the wrong choice of protective coating.

Hemp is made of cellulose (it has even more than wood!) and mold likes cellulose. If you put plain wet hemp in a plastic bag and seal it, it will get moldy.

Hempcrete has less risk for mold. This is because the hemp in hempcrete is mixed with a lime binder that makes it possible for the hempcrete to harden.

Lime is what gives hempcrete its mold-resistant property. Lime is alkaline (high pH). Mold, in general, doesn’t like alkaline environments. When the lime binder is mixed in and coats the hemp pieces, it essentially creates an inorganic, alkaline buffer that mold cannot survive in.

However, one study I read found that mold was still able to grow, even in the presence of lime binder, when the hempcrete wall was exposed to heavy rain.

A lot depends on using the right binder, mixing it correctly, making sure anything put on the walls is vapor-permeable, and avoiding bulk water (rain, roof-run off, etc.)

When a hempcrete house is properly planned and correctly built, the chances of mold growing are likely less with hempcrete than with traditional building materials.

Do your research on binders before choosing one. There are binders out there that have caused mold problems.

If you want to avoid mold in your future healthy house, proper planning for moisture management (weather and vapor) is essential.

Please find a qualified architect or building science professional to create a plan for your new healthy home.

What climates are safe for building with hempcrete?

This study found the most microbial growth in a simulated tropical environment. The Mediterranean climate simulation induced the growth of six species of bacteria and four species of fungi, with moderate diversity. In the arid climate simulation, only four species of bacteria and two species of fungi appeared. Hempcrete certainly faired the best in the arid desert climate simulation.

There are many hempcrete houses in the rainy UK, as well as institutional buildings and multi-family complexes. In North America, there are hempcrete buildings in coastal North Carolina to snowy Idaho and cold, wet Canada. If you intend to build in a wet climate you should go visit some of these homes when possible.

Since hempcrete is an insulation, it should be just as safe as something like blown-in cellulose. The details will change depending on the climate, however – humid, dry, rainy, cold, warm, etc.

It might be necessary to protect the exterior wall with large overhanging eaves, or sheathing combined with a rain screen (gap) and siding.

This is where an experienced architect can help you determine the details that are necessary for your location to avoid mold and rot.

Is Hempcrete Cost-Effective?

- The cost appears to be 10-30% more than typical wood construction.

- Much of it has to be imported (and it can be difficult to source, depending on where you live).

- It takes a long time to dry which can slow down the build.

- The cost depends on the method you use.

- A double stud wall is more expensive (double cost).

- There are very few experienced architects or builders.

- Blocks and precast panels tend to be more expensive because they need to be cast individually unlike a whole wall that can be cast as one.

Related post: on more natural building wall systems to consider.

Where to Learn More About Hempcrete

Helpful books:

- The Hempcrete Book: Designing and building with hemp-lime by William Stanwix and Alex Sparrow

- Essential Hempcrete Construction: The complete step-by-step guide by Chris Magwood

Helpful videos:

Trainings:

- Endeavor Centre – Canada

- UK Hempcrete

Products:

- Hempitecture – hempcrete samples, hemp hurd, blocks, hempwool, binder, and tools/machinery

- Hemp Eco Systems

- Tradical Hempcrete

- Tradical Hembuild – Pre-cast wall panels

- Sativa Building Systems – insulated panels

- Just BioFiber – blocks

- NatureFibres – insulation panels

- CannaGrove HempBoard (out of business)

Design / Build

USA

- Hempitecture – Idaho

- Homeland Hempcrete – North Dakota

- New Frameworks – Vermont

Europe

Corinne Segura holds certificates in Building Biology, Healthier Materials and Sustainable Buildings, and more. She has 10 years of experience helping others create healthy homes.

If you would like to support the research behind this blog you can make a donation via Kofi!

Engre

Thank you for sharing this article. It was very interesting to learn about such a material for the construction of houses as hemp. I think this is perfect for building houses using 3D printing. I am interested in calculating the cost of such a house. By the way, engineering services for the design of houses can be found on the Engre b2b platform.