Thermafoil, Melamine, and Laminate are all plastics used to cover substrates on kitchen and bathroom cabinets to create a hard, water-resistant finish.

The substrates of cabinets doors and drawer fronts include particleboard and MDF. The boxes are plywood or particleboard.

This post explains the material composition of these plastic covering options – what they are made of and any potential for toxicity and offgassing of VOCs.

I will look at which are the lowest VOC options and how to seal in any offgassing to make them non-toxic, or at least less toxic.

My main post on Cabinet Brands is here.

Melamine Cabinets

Melamine is Medium Density Laminate – MDL, a melamine resin-coated paper that can have a printed pattern or solid color on it.

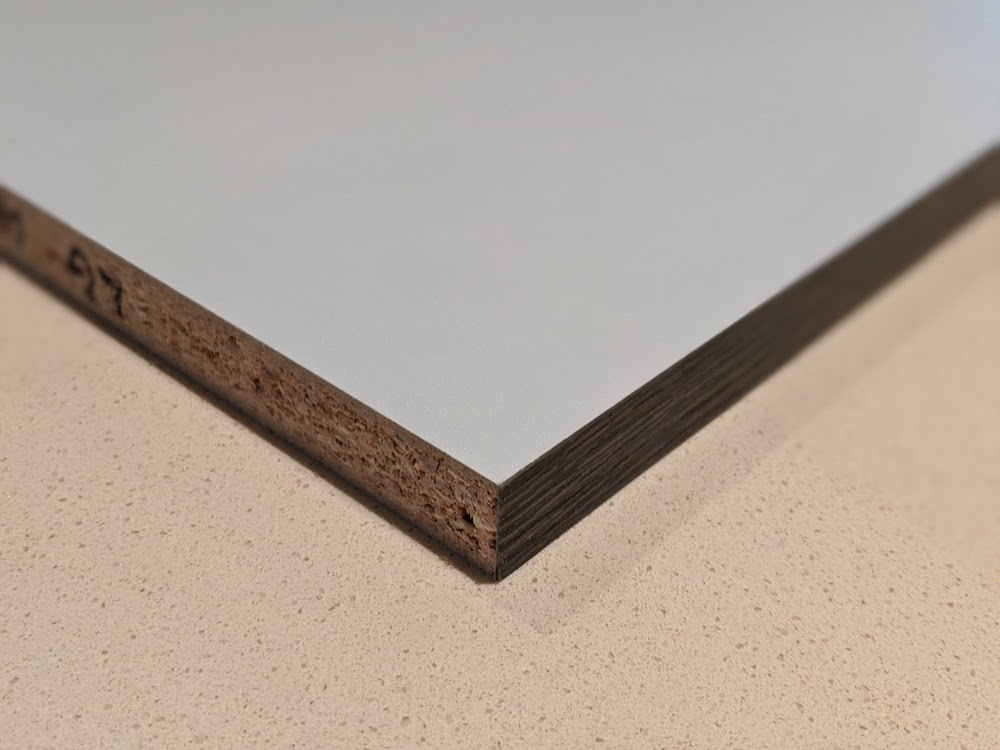

In this case, it is laminated onto the substrate, usually particleboard, but sometimes MDF.

While some cabinets like IKEA use Melamine as the exterior finish, I often see it as the interior finish of Laminate cabinets.

It is less expensive than the Laminate described in the next section. It’s not as strong and impact-resistant but otherwise it’s very similar.

Technically, melamine is just one type of or Low-Pressure Decorative Laminate. The other type is made of polyester, but melamine is the most common.

Most products are prelaminated to particleboard or medium-density fiberboard cores. In other words, unlike the Laminate described below, you don’t usually find this as a stand-alone plastic sheet product.

Laminate

Laminate, also known as Plastic Laminate or HPDL (High Pressure Decorative Laminate) is in the case of cabinets, laminated onto a core as the face covering.

Decorative laminate is produced by fusing together kraft paper saturated with phenolic formaldehyde resin, together with a layer of melamine-saturated decorative paper under heat and pressure.

I have also seen this referred to as High-Density Plastic Laminate (HDPL).

The laminate layer is usually 1/32” or 1/16” thick. 1/32″ is used vertically on cabinets.

Plastic laminate comes in many designs, you can have a shiny plastic look, or more commonly right now, a wood look. It often has a texture to help it look more like wood.

It’s usually available in more colors and patterns than Melamine.

I see it commonly on the faces of commercial cabinets used in apartment buildings.

It’s also the same product that is used to make laminate countertops the best-known brand is Formica.

In the case of countertops, you can buy the sheets of laminate as a stand-alone product (not only attached to the substrate). 1/16th is the thickness of Laminate countertops.

What is a Thermofoil Cabinet?

Thermofoil does not actually contain any foil or metal. It is a thin layer of PVC/vinyl that is vacuum-pressed onto cabinet doors and drawer fronts.

The substrate is usually medium-density fiberboard (MDF).

To make the Thermafoil finish the MDF cabinet door and drawer bases are placed in the press. A flexible layer of 100 percent vinyl is laid on with an adhesive and vacuumed pressed.

The vinyl layer has an integrated color or design, and like the Melamine, there is no paint or coating on top.

This could also be called a thermoplastic sheet. It is possible to make thermoplastic with an acrylic plastic. But whenever I have seen Thermafoil listed as a cabinet finish it is vinyl.

Thermofoil vs. Laminate/Melamine

Melamine and Laminate cabinets are often confused with Thermofoil, but they are not the same material.

Melamine and Laminate are made of melamine plastic, Thermafoil is vinyl.

You can tell them apart by the following:

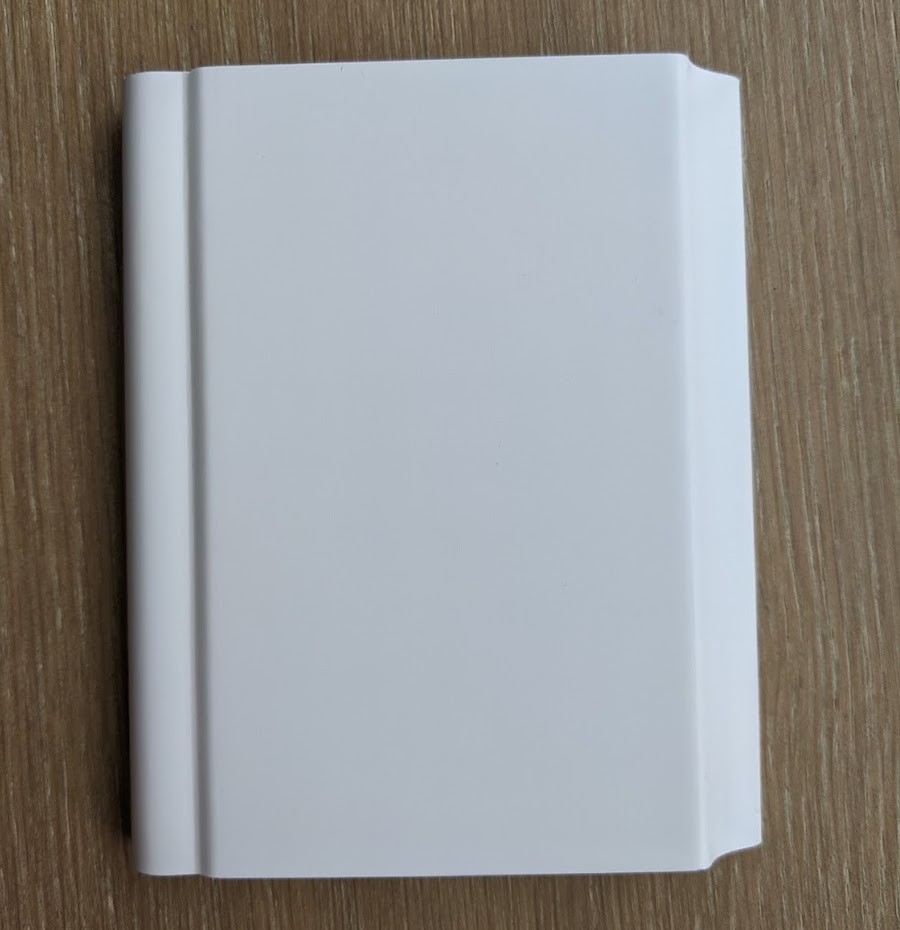

- Thermafoil is thicker, softer feeling, peels off more easily, and is more flexible. If you can see the edge of it you can compare it to the photo above.

- Laminate and Melamine are thinner and harder plastics. They don’t peel off as easily.

- Melamine is thinner than Laminate, though they are made of the same plastic.

Offgassing of Laminate, Melamine, and Thermafoil

Melamine plastics are fairly safe plastics. While there is a little bit of formaldehyde on the backside, the plastic itself is quite tolerable for the chemically sensitive. I cannot pick up offgassing on the plastic side since it blocks the formaldehyde.

Thermafoil which is vinyl certainly has an odor at least when new. The odor of vinyl lasts longer than other plastics in my experience. Certainly, any flexible vinyl can be expected to have a chemical odor.

Both particleboard and MDF offgas formaldehyde, the levels can be found here. In almost all of the world now they meet CARB II levels.

Sealing in Offgassing in Cabinets

Laminate and Melamine both provide a good amount of sealing in of the formaldehyde in the particleboard and MDF substrates. For many people, this is a good enough seal.

Not all brands have a complete encasement of the engineered woods. It is ideal if they are fully encased on all sides and edges.

If they have raw edges you should add a sealant there to seal in the formaldehyde. You might have to look for the edges, they might for example be raw on the edges of the shelves, which you won’t see until you take out the shelves.

You should also plug the holes that were made to adjust the shelving and seal over those too. Anywhere where there is some exposure to the particleboard or fiberboard you should seal.

The edges can be sealed with AFM Safeseal or Zinsser Shellac.

AFM Safeseal can be used anywhere where there is a raw wood edge offgassing formaldehyde. It can be layered with Shellac, use the AFM first.

Shellac can be used anywhere where you have a mix of sealing over wood and plastic – for example when sealing in the shelving holes, or edges of laminate that are coming apart.

Corinne Segura holds certificates in Building Biology, Healthier Materials and Sustainable Buildings, and more. She has 10 years of experience helping others create healthy homes.

Sources:

https://woodworkinstitute.com/wp-content/uploads/2015/05/Sec4_2ndEdAWS_SmBkMrkd_141001.pdf

https://www.chicagotribune.com/news/ct-xpm-1996-05-04-9605040048-story.html

Joanna

I’m looking to replace my kitchen cabinet doors. The company offers only thermafoil foil or painted MDF. Will the paint cover the offgassing smell from the

MDF? Does MDF have a strong odor and will it go away With time?

Thank you

Corinne Segura

Paint is not a great block of formaldehyde from MDF, though depending on the type of paint it can reduce the offgassing. depending on your sense of smell yes it smells like formaldhdey (rarely you will see formaldehyde free MDF) and it does take a while to dissapate, years to fully offgas.

Joanna

Thank you!

Jane

We are in the process of renovating a bathroom and have the option of what materials to use for new shelving in a triangular closet in the bathroom of our house built in 1904. I would prefer white melamine over plywood, Not sure if they can custom make these with melamine on the thin edge and use a sealer on the raw edge? As a person who has survived cancer, I am VERY appreciative of info and resources you share.

Brooke

I’m looking at purchasing a desk , the desk top is made from laminated melamine top has a woodgrain finish. I reached out to the company to inquire about formaldehyde use in the wood and they said the content of their melamine tops do not include formaldehyde, is this possible ?

Corinne

Melamine is laminated onto an engineered wood, either particleboard or MDF. It’s going to be particleboard in a desk, almost certainly, which is definitely made with formaldehyde. If it’s encased on all sides with melamine, that can stop the offgassing.

Maureen Macdonald

I do have a reaction to even one of my cupboards inside that is 15 years old. But my husband had a reaction when we were looking at a cupboard wood door sample. I understand stone wood is different? Do you have informatiin on that?

Corinne

I don’t know what stone wood is.