The following are concrete and natural earth-based wall build systems that do not offgas toxins and are suitable for the chemically sensitive.

These are alternative build types, the options for building a healthy home apart from the standard timber frame, fiberglass, and gypsum boards.

Drywall now has its own dedicated post here: Guide to Non-Toxic Drywall Types and Brands.

This article contains affiliate links, upon purchase I make a small commission at no extra cost to you.

Pumicecrete Walls

A mix of pumice and concrete is poured into forms to create these non-toxic walls. They can be made load-bearing with a concrete beam. Test pumice for radioactivity and for odors that it may have picked up prior to installation.

Check out Margaret’s blog where she outlines the build of her healthy pumicecrete house.

HempCrete

An interesting material making a comeback, HempCrete is made of hemp and a lime-based binder. Hempcrete is either used to replace insulation in the walls or as the final wall itself.

They are not load-bearing so they are made with a wood frame.

HempCrete claims to not mold, but a natural fiber in a breathable wall is not something I would consider mold-proof.

See my detailed post on HempCrete for much more info.

Consult with an architect to make sure this is right for your climate.

Wood Insulated Concrete Forms

Forms are made of a mix of remineralized wood and concrete. Inside, rebar is used as reinforcement and then they are filled with concrete.

Insulative fibers can be added or they can be filled with part concrete and part clay or non-toxic insulation. Brands include Nexcem (Durisol) and Faswall.

Faswall is currently the only brand available in the US (2017). Nexum is available is based in Canada and they sell and ship across North America as well as to Australia and other Pacific Rim countries.

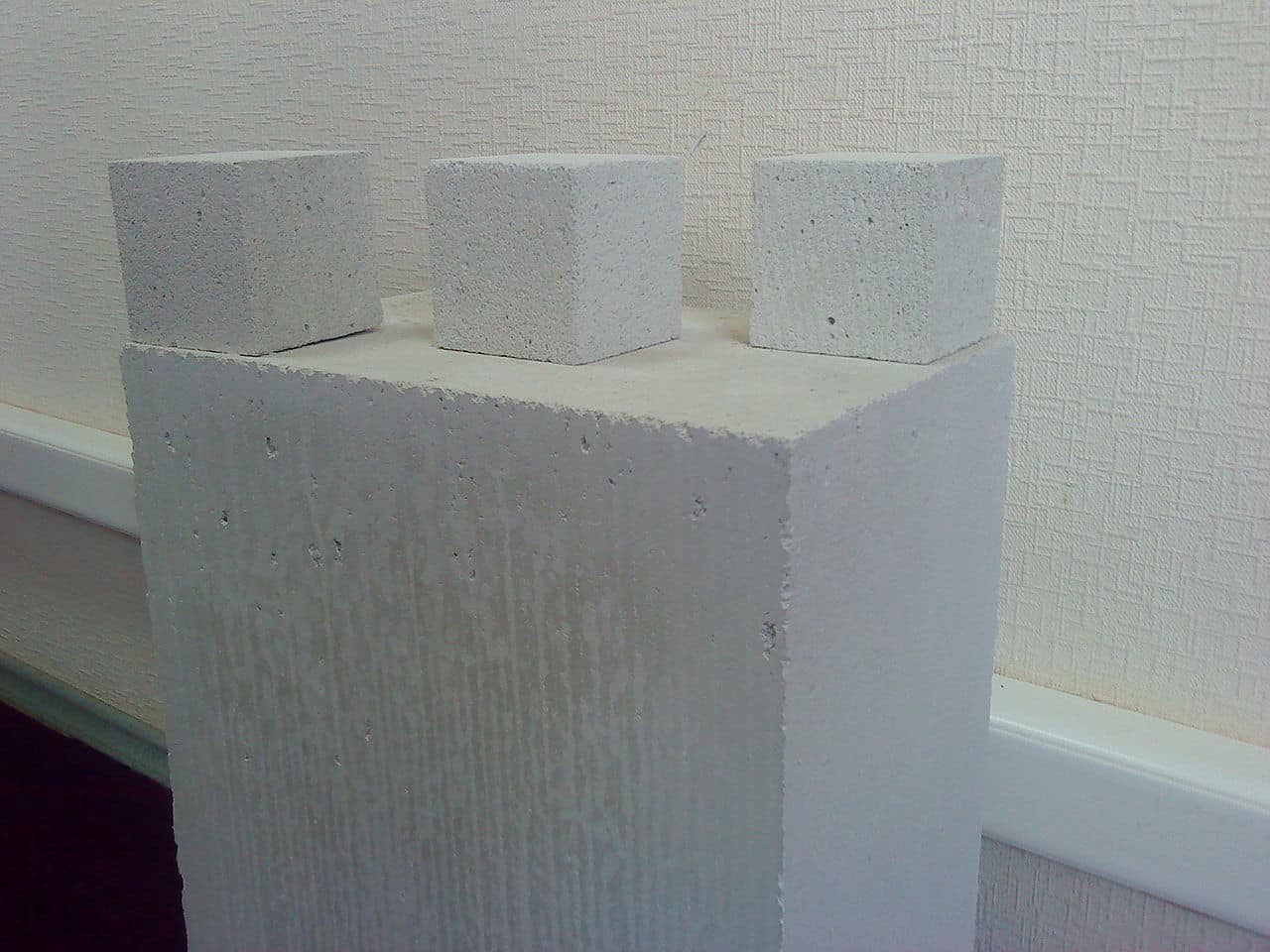

Aerated Autoclaved Concrete (AAC)

Tiles of autoclaved aerated concrete by Sealle CC BY-SA 3.0

Concrete-based blocks made from quartz, lime or cement, and aluminum powder. Test thin-set mortar for sensitivity. Hebel is one brand in the US. It’s not approved in California (2017).

There have been some problems with AAC collapsing that you should read about here. Though it can still be used for non-load-bearing walls.

Insulated Concrete Form ICF

Nudura Blocks (US and Canada) and Fox Block (US and Canada) are the most popular brands right now. ICF could mean different types of foam with concrete fill, but typically it is EPS. See my post on Insulation for a detailed review of EPS. Nadura has a dye. Both have flame retardants.

| Is Concrete Non-Toxic? Portland Cement is non-toxic. Sensitive folks may want to confirm that it is free of admixtures such as air entrainment and water-reducing agents, accelerants and retardants, and superplasticizers. Ceramic Cement (Magnesium Cement) is also generally a non-toxic option. Which Concrete Aggregates are Chemical-Free? Natural non-toxic mineral aggregates should be used. Toxic aggregates can include crushed brick, crushed sandstone, concrete slag, fly ash, cinder, and volcanic materials other than pumice. (Source: Prescriptions for a Healthy House). |

Earthern Walls – Cob, Adobe, Light Stray Clay, Straw Bale, and Rammed Earth

These are all different types of walls made of clay, straw, and sand.

Houses made of all-natural materials feel great to be in and there is no need to worry about any offgassing.

However, there are precautions that should be taken to avoid mold. These types of buildings might be best suited to dry climates so that there is no chance of mold forming. Some people seem to be doing very well in adobe houses in the south-western US. Note that adobe is usually stabilized with asphalt.

If straw is used in the walls it should be carefully sourced to be free of mold and pesticides. When building with cob, adobe, or light clay straw there needs to be a dependable dry season of three months for the walls to dry out properly.

They are particularly suited to be heated with wood stoves as that dry out the walls well in the rainy and damp seasons (source: Econest).

An above-grade stem wall and proper drainage around the house are also very important to keep the walls from getting damp.

I’m hearing some bad stories of mold forming on cob and straw bale homes in cold climates, this is likely due to high humidity inside in the winter. I do not feel confident enough in this building system to recommend it for climates where it is not a native building practice.

Another natural wall system worth mentioning in a little more detail, Rammed Earth, uses sand, gravel, and clay and has had an interesting development recently. Foam has been added for insulation and steel for support, and 5-10% cement is added to the clay mixture. It’s called Stabilized Insulated Rammed Earth.

Water does not penetrate the walls, however concrete, especially when not climate controlled is extremely prone to mustiness.

Corinne Segura holds certificates in Building Biology, Healthier Materials and Sustainable Buildings, and more. She has 10 years of experience helping others create healthy homes.

Did you find this post helpful? If so you can buy me a coffee to support the research behind this blog. Thank you!

Seebo

Hey there,

In the green box above, you write

“Toxic aggregates include crushed brick, crushed sandstone, concrete slag, fly ash, cinder, and volcanic materials other than pumice”.

I’m curious what the issue is with cinders. I live in a volcanic area and have been considering building an earthbag house with the bags filled with cinders since they’re plentiful locally and a good insulator.

Thanks!

Corinne Segura

https://www.researchgate.net/publication/251941402_Health_Risk_Assessment_of_Heavy_Metals_in_Medical_Fly_Ash_and_Cinder_from_Incineration

Seebo

That’s referring to cinders obtained from the incineration of medical waste though.

Are there known issues with volcanic cinders aka scoria from an actual cinder cone volcano?

Corinne Segura

It’s the same problem, that falls under volcanic materials other than pumice. It contains toxic metals.

Kyle

Thank you Corinne for all your great work! This website is a phenomenal resource. I am currently setting up a yurt to live in, mold free and hopefully minimal chemical, while I build and all natural adobe house. Do you have any thoughts to chemical exposure in the prefab yurt kits?

Corinne

The exterior is usually vinyl which could take some time to offgas.

Trish

what about SABS (saebi alternative building systems)? Using EPS foam glued with HILTI Polyurethane and GFRC sprayed or trowelled on the outside of the foam? will the GFRC keep the EPS and PU adhesive contained or will it seep through the GFRC or is the GFRC the problem

Crystal

We chose Comfort Block by Genest Concrete in Maine for our non toxic home. The roof is made of wood trusses with dense packed cellulose for insulation.

Syrena C.

Hi Corinne!

We are considering a rammed earth home. Now, concerned about potential of musty odors, though. With that small amount of concrete, would that be an issue? Have you visited any rammed earth homes that had that issue?

Thank you!