Converting a Cargo Trailer into a Travel Trailer – Mold Preventative, Low-Toxin Design

I’m converting a small cargo trailer into a tiny trailer that can be used for sleeping and living. In the end, this model is only useful as a portable kitchen and bath. Other models are sturdier and may work better as insulated conversions.

The cargo trailer is a TNT brand DBL ‘A’ 6×12, White, 12″ extra height making it about 7 ft high on the inside. The extra height is well worth it I think for a sense of space.

Side and roof vent (side vents are so small that they bring in very little air. The roof vent can only be wide open if it’s not raining). RV door lock that locks from the inside (vital) and barn doors that lock from the outside (easier to handle than the ramp door). You may want to move the lock to the inside when living in it. Front and roof are curved in this one.

I recommend all of the products here, some products have affiliate programs and some do not. Upon purchase, I earn a small commission through affiliate links at no extra cost to you.

Costs in Canadian Dollars:

- $6100 cost of trailer

- $3600 cost of renos at trailer shop – metal floors, install window, take out plywood (much cheaper, and probably faster if you have the factory do these.)

- $1500 cost of insulation

- Labor for insulation and vapor barrier, foil, and glue – lost track

- $1300 Electrical (+ $185 for CSA inspection and approval – allowing me to legally park the trailer in Canada)

I have seen better prices in the US, you can go smaller and get a better price, but for me, 6×12 is the minimum amount of space needed to make a happy little home.

Joey was able to do this for $7000 with the factory doing most of the work. In the Facebook group Mold Avoiders on the Road, you can see people having smaller trailers renovated for under $4000.

Necessary Renovations:

Remove plywood.

Install window – 24 x 30 vinyl awning style to stay open even during the rain (you’re going to need air in such a small space). It’s vertical so that the framing did not need to be cut. I do not find the hard vinyl has a smell but you can use aluminum.

I wish I had put in two as it’s nice to have windows. One does bring in plenty of light through, along with the vent on the roof.

You can look for an RV window or you can use a tempered glass house window and reinforce the framing around it.

Install metal flooring 3/16 hot roll plate steel flooring, 1000 for the metal + welding. See this thread for an in-depth discussion on what type of metal to use.

Electrical work

A 30 amp panel with a campground plug and 4 outlets inside. You may be able to make do with fewer outlets but the electrician wanted a dedicated outlet for the fridge and one for the heater. Then I have one near the bed for a computer etc, and there is one up high to string up a light and run any kitchen appliances.

Have these renos done by the factory and not after you buy it. This was a huge mistake that cost me a lot of money and didn’t save me any time like I thought it would.

I should have known better as I had read Joey’s conversion story (highly recommend reading that for another version of a conversion and some ideas on what you might want to add. (I disagree that foam doesn’t provide a lot of protection from the cold and heat. 2 inches of XPS foam is R-10, that is really good).

How long it will take to customize one depends on the brand, the factory, and the time of year. Add 2-3 weeks on to their estimate.

The back door in mine has structural plywood so that still has to be removed and needs metal reinforcements. The front end had plywood between the frame and the skin which was a major pain to remove. Look for a brand that does not have these two issues and you will save a lot of money.

If you want to do it yourself check out this thread (you have to sign up). Watching someone’s account of doing it herself is well worth it. You will see tips on taking out the plywood and choosing a metal for the floor.

Do the Walls Need Reinforcement?

A big question with cargo trailers is if you need wall reinforcement when you remove the plywood. There are two answers to this.

The first is that it depends on the brand, some brands will tell you that their trailer is good to go with no plywood, these have thicker frames like the steel CM trailers. Or some companies can customize it with thicker frames. See the pictures below.

The second answer is that the companies might say they are not strong enough but people leave it un-reinforced anyway. Erik Johnson, me and two other mold avoiders have taken out the plywood and not added anything that would replace it structurally.

Mine started leaking and the company that sold it to me claims that the reason it leaked is that the plywood was taken out and this means there is less stability and it’s easy for pieces to come apart and caulking to come loose. I have braced mine since.

If they won’t customize it without plywood, remove that part yourself and reinforce it (or don’t) yourself.

The first picture is a customized trailer reinforced with aluminum frames. Very robust. If you look closely you can see tape between the frame and the exterior, a mold risk.

The second picture is a CM all steel trailer with a robust steel frame, the frame is standard and the company does not recommend reinforcement.

The third picture is a standard frame, with plywood removed. Though it’s not reinforced the owner is doing just fine with moving it around frequently. The brand is Victory.

This picture is my trailer it has the least robust frame of the bunch, while the seller advised that it could be reinforced for longer trips (he told me this after the insulation was up). I have now braced/added strapping.

Toxicity of a New Cargo Trailer:

A cargo trailer smells much stronger than someone might anticipate a new metal box to smell. An extreme avoider in a hot climate would leave it sit for about a year before using.

I have seen two people who have turned around and sold them soon after buying due to the strong smell. Mine is now a year old and not totally offgassed.

The smell comes mostly from the body of the trailer. It is a glue smell and may also be from oils on the metal. There are many other parts that are non-metal (differ slightly between brands) that may include:

Caulk of different types, double-sided tape (you do not want to buy a cargo trailer with tape in the frame – this is a mold risk), plastic on the back of the RV door, plastic and glue (very smelly) in the vents to the point that you will likely not be able to use these vents for air, rubber, and foam (glued on) can be found around the RV door, around the barn doors, and possibly around the window on some models, there may be tape holding up wiring, there is the usual plastic coating on the wiring, plastic light and light switch may be included, there may be spray paint on wiring, there may be caps on bolts, screen on top vent, there is also exterior paint which some people have said they are offgassing but I could not pick up a smell on.

In such a small space there are also the tires on the outside to consider – on a hot day you will smell these.

Rustproofing chemicals may also be added to the frame. (Thanks to Madonna Ramp for some of these materials from other brands).

A lot of this can be covered and you can see in mine that it is almost completely sealed up. If you buy one and it smells strong, give it time and/or seal it up like I did mine.

Every trailer takes time to offgas. Someone was able to get the company Mirage to build without glue or caulk, but she was not able to tolerate the trailer brand new. I would not recommend leaving out glue and caulk.

Buying a Used Cargo Trailer:

I did not see any used cargo trailers in my area when I was looking but you can sometimes find these. You would want to know what it was used for. Look for gunk and rust that will accumulate at the bottom around the frame.

Building out the Interior – How Mine was Done (The Second Time)

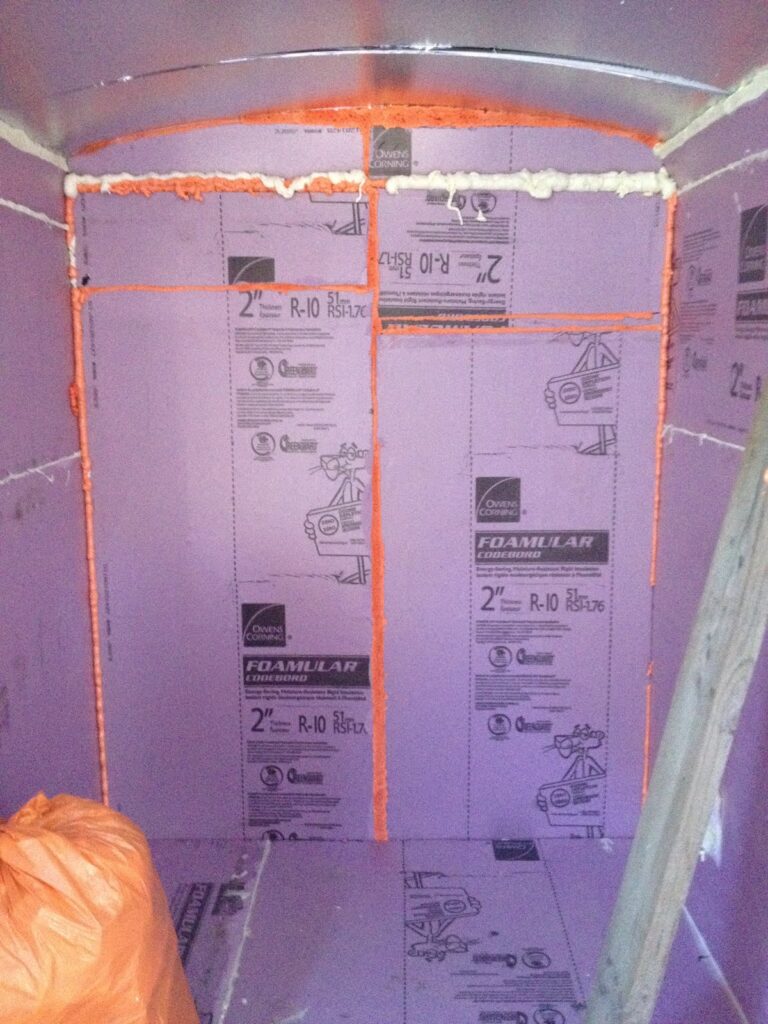

- XPS Owens Corning Foam 2 inches on walls and floor (you can also use polyiso, the most well-tolerated foam, or EPS styrofoam which is not a vapor barrier on its own but is usually faced with foil or plastic). 2 inches XPS is R-10. If you are going to a climate that is extremely cold, add another layer of foam – polyiso or XPS on the inside until you get a high enough R-value for your climate. The reason I chose XPS is that it has a high R-value and it doesn’t lose its R-value in very cold weather like polyiso does. I also could not find polyiso in my town.

- 1 inch Foil-backed EPS on ceiling (because I needed something thin enough and flexible enough to be curved on the ceiling) (Note: This is backward, there should be more insulation on the roof but I wanted the roof to stay curved and the insulation to stay between the frame so I kept it simple.). The brand was R-Tech but I can’t find a link for this. I can add another layer of 1-inch foam if it gets too cold.

- Great Stuff spray foam should be placed behind the foam and on the gaps of the rigid foam (airtight so no moisture gets behind the foam). There is one for small gaps and one for larger gaps you will need some of each. This then needs to be braced and riveted to the structure which is hard to do in many types of cargo trailers and I would not recommend these standard brands like the one I bought.

- GE 100% silicone for touch-ups to waterproof the exterior

- A Fantastic Fan in the roof vent would be helpful for ventilation, drawing air out of the top will draw it in the window and turn over a lot of air. The fans also help with humidity. This has to be wired in with the electrical.

There is a rumor that spray foam will crumble with movement in a trailer but speaking with the company Great Stuff and some folks who have taken apart trailers they have not seen this be a problem.

EMFs:

All this metal and foil did not stop wifi or cell phone reception – it lowered my wifi connection only slightly. If you are concerned about EMFs (electromagnetic fields) consult with an EMF specialist and test out a metal structure before buying. In theory, it is a Faraday Cage that blocks out some external sources of EMFs and may intensify what is on the inside.

Fixing the leaks

My TNT Mirage Trailer has a number of poorly built aspects. The company took no responsibility for this and the leaks.

What has to be fixed on this model or checked on any model: The back doors were leaking, the top sill needed caulking, the door seals were not done right, the doors were bulging at points, bending the doors and adding gaps for leaks. The front diamond plate had nothing behind it, it was a negative lap – a poor design, the front wall should come all the way down. The front plastic cap on the top roof is also a negative lap.

Vertical seams have the ability to let in water in a big storm or when driving it in the rain. Always check windows, doors, and any openings. Screws should be caulked as well. Look for a well-done roof design. This roof design is good. I have seen custom designs with vulnerable roof seams.

Aggressively hose test this before adding insulation and know where the weak points are. After moving it is when things are most likely to come open.

When recaulking metal parts, attempt to open things up and get caulking between parts and not just over the seams.

These trailers are difficult and I would not attempt insulation in this style/brand again.

Erik Johnson’s Cargo Trailer:

Erik is the pioneer of cargo trailer living. He called his trailer and camper MECUs (Mobile Environmental Containment Unit). Erik used EPS foam without flame retardants. I don’t know how he sourced this but I would think this is the kind used for packing, not insulation.

In Erik’s trailer, he left a gap (like I did at first) between the foam and the exterior. He put in weep holes at the bottom in case condensation did find its way to the back. Some trailers like mine come with weep holes.

He has said that there has not been any condensation at the back and he has had this for more than a decade. I put the insulation in front of the frame which created a space naturally behind it (though my floors and ceiling have no space).

This method did not work for me, major condensation formed behind the walls and I don’t know anyone that was able to get this to work.

Here is a video of his camper which is done like his cargo.

Other Trailer Options:

You can build out the interior as much or as little as you like.

- You could add batteries but consider how long these will last you away from plug-in power.

- You could add solar panels but this doesn’t get you a lot of power, it may be easier to just buy a solar kit that is portable that is made for camping.

- If showering in another building, campsite bathroom, or outdoor shower is not an option for you, you could install basic plumbing. You would want to avoid tanks and have very simple plumbing that goes directly out to a bucket or pipes out into a greywater system. You will have to make sure you are following the rules with greywater here. I want to avoid all cooking, showering, and clothes drying inside to keep humidity down.

- Options for outdoor showers include simple bucket showers, passive solar shower (that one is PVC-free, unlike most of them), active portable hot water shower (this one comes recommended by mold avoiders), or an outdoor tub big enough to bathe in. A privacy tent can be used to shower outside or set up a toilet outside. You can also DIY and set up something simple like house wrap around 3 trees, or tie a string around 3 trees and the string holds up shower curtains.

- You could install a simple camping or composting toilet inside or use it outside if you need to: some of the options are Luggable Loo, Mini Porta Potty, or Laveo Dry Flush.

Finishing the Interior:

Walls

Floors

For now I’m using these mats on the floor temporarily. They smell like straw.

I am currently offgassing Marmoleum (takes one month in sun to offgas) but I don’t like that there’s a jute backing under the Marmoleum against the metal, that’s a mold risk).

Note: Flooring I ruled out: Thermacork decorative cork the only cork I know of that is heat-pressed with nothing added – not good for floors. It flakes easily and won’t last long.

Cork underlayment – I bought this and tested another one that claimed 0 VOC (volatile organic compounds). It is going to need a lot of time to offgas despite these “0 VOC” polyurethane glues (not at all). A year later I have not offgassed the cork floorings (though they were not out in the sun for a year).

If you have space, I like this organizer.

Heating, Cooling, Lighting, Laundry:

- I’m have this light bulb up (the cord smelled strong and offgassed in my car for a while but then was fine for me). I also like this little nightlight but it won’t provide much light.

- I will mount this silent, energy-efficient, space-saving heater (which smelled at first but did offgas quickly in the sun) with this thermostat.

- In the summer I will use a portable AC. I throw them away every fall as they tend to go moldy after one season or two and I have nowhere to store them.

- I’m using this clothes dryer to dry my clothes and I love it. I don’t want to add humidity in the trailer so I am using it outside undercover. It works well even in humid and cold outdoor temperatures (and it’s not as mini as it looks). I have used this successfully down to freezing. I have not tried it much before freezing but I’m still really happy with it.

Kitchen:

- I bought a blue retro fridge (no longer available online) which needed a lot of offgassing outside including running it outside. It smelled more than other brands I have tried like Danby.

- I’m using this kitchen island which offgassed fairly quickly but you could use a metal version if you want to avoid wood (and wood sealers and glue).

- I offgassed this cutting board pretty fast. I’m just posting that because I love it so much

- Thrift shop bowls

- This hanging basket to organize kitchen items

- I’m using a pressure cooker to cook – you can make almost anything in this. If you use it outside or at least release the steam outside you will have very little or no added moisture to the trailer. You can get away with no other stove, oven or microwave. You just need an extension cord to use it outside.

- I’m going to buy the travel Berkey for drinking water, there is no plumbing in the trailer. Berkey is ideal for well water and water from campsites if you are not buying water.

Bedding:

In a high-humidity situation like a trailer, tent, or other camping structure it’s important to have a bed and bedding that will not go moldy.

My bed will be up on slats soon (right now I am turning the Thermarest over every few days – it went moldy so it is crucial to get it off the ground onto slats).

Cotton does not hold up well in high humidity, so I have used more mold-resistant materials.

- I’m using my super-duper bed-like Thermarest

- Polyester sleeping bag

- Polyester pillow

- Polyester pillowcase and sheets (or the one that is made for Thermarest)

- Microfiber towel (no cotton)

- This heating blanket keeps me warm on very little electricity. If you are worried about EMFs then an infrared heating mat is supposed to be

Corinne Segura holds certificates in Building Biology, Healthier Materials and Sustainable Buildings, and more. She has 10 years of experience helping others create healthy homes.

Did you find this post helpful? If so you can buy me a coffee to support the research behind this blog. Thank you!

Elle

Hi Corinne,

Would you mind dropping the link for the portable AC you mention here? The current link goes to a programmable thermostat. I’m on the hunt for a portable AC that offgasses minimally.

Thanks!

Corinne

I don’t remember which one I used its been quite a few years

Elle

Thanks for reply. Any current recommendations?

Bruno John

Normally, electricity for converted cargo trailers tends to come from a 12-volt battery connected to an inverter. However, the supply to originate from solar panels or a lithium RV battery is better?

Eli Richardson

Wow, it’s interesting how you turned your cargo trailer into one that could be used during camping trips. My sister loves DIY projects and camping, and I think she’d love the idea of buying a cargo trailer and doing a make-over to it, so I’ll suggest it when I see her later. Thanks for the tips on cargo trailers and how to renovate one to fit your needs.

Braden bills

I want to make sure that I can get my stuff transported, but I’m not sure what to do for that. It makes sense that I would want to get an enclosed trailer for this. That seems like a good way to ensure that I put everything together properly.

Michael Clark

Creating a camper from a cargo trailer necessitates taking measurements, drawing a plan, locating and purchasing necessary components, and finally installing each component. It may appear to be a difficult task, especially for novices.

Jason

Hi Corinne, thanks for the great article. I was wondering about this statement “Great Stuff spray foam should be placed behind the foam and on the gaps of the rigid foam (airtight so no moisture gets behind the foam).”, Could you please explain the “Behind the foam bit, I would like to get my build done correctly, so any tips you can give me are really helpful.

Thanks again.

Corinne

See the van article for more info on that.

Jim

Please stop using abbreviations. Some of us don’t know what they mean.

Mike Pearl

I really appreciated this documentation as it offered some interesting and unique perspectives on a trailer build. I have a newer aluminum framed cargo trailer with screwless walls, its hard to be in there with the off gas smell. My walls are 1×1″ framing 16″ OC then 1/2″ OSB board, the roof is 1.5″ x 1″ 24 OC (no OSB). I thought about using 1″ Thinsulate between the side wall ribs. I am in the Pacific NW where mold is a concern andI wondered (after reading your post) if it would be better to leave the area between the wall studs as open air space for better airflow (like a rain screen, but you wrote that the weep holes didn’t work for ya). Sound dampening is very important because I am a musician and am trying to limit road noise or people hearing me practice. Trailer metal walls can vibrate the sound in either direction so I say yes to the Thinsulate.

I might go right over top the OSB with a continuous layer (also serves as a thermal break) of min 1.5″ rigid foam ISO and Owenscoring 705 Rigid fiberglass. Then install 1×3 (actual 3/4″ x 1.5″) furring strips over that and anchored to the OSB somehow. The furring strips would become the (stud-like) mounting points for shelves/cabinets. The 3/4″ gap/airspace they give could be place to run wire. I am thinking a lot about how much weight those furring strips will hold if I decide to mount something heavier to the wall? It’s the same concept as internally insulating a concrete basement wall. I would also like to run internal ducting HVAC ventilation system with inline fans instead of a fantastic fan. I’d loose a lot of living space though. Weighing the tradeoffs can make a person batty!

JeckRyan

First off, with all due respect, all cargo trailer builders state that these cargo trailers are just simply for cargo. They are not meant to be used as a living space. So they are in no way at fault. The consumer/converter is the one that must require the skill, knowledge and understanding of converting his or her cargo trailer into a space they can enjoy as a RV trailer. An understanding of metals, insulation, window and interior finishing materials, is a must if you are wanting a successful care free RV conversion. Read, read, read the information of professionals and learn from the mistakes of others that have shared the do’s and don’ts of conversion. You can convert almost anything as a living space. From shipping containers to an automobile. I have even heard of a few people that have converted retired jet airliners into a home. Take your time, plan it all out and ask professionals before you start. This can help you avoid a situation you don’t want to [ut yourself into. Most of all have fun doing it. I enjoy working on my project that never seems to get beyond a needed update or a little do over. Just like any other living space.

Nick.m

Hi there , that was a lots of info , thanks , I was able to compare what I did with mine ( build from a brand new trailer spring 2020) I don’t think I made many mistake I build it the right way .

Only one question for you . I’m currently out hunting northern Alberta atm and I’m obviously getting condensation around the toy-hauler back door metal frame surrounding

( hot in cold out ) any hint on what I could be doing in my case ? I have been thinking about many option but nothing seem like a good idea for now .

I pretty much need something removable ?

Thanks Nick

Claire

Hello!

I wanted to ask how you removed the plywood from in between the siding and frame. Thank you!!!

Best,

Claire

Nick.M

I’m guessing your screws are all spinning are they not ?

Unknown

Thanks for a lot of info. I have to say this is not remotely chemical-free, despite the website title. I wouldn't want to, neither would be able to be around most materials mentioned here. And not sure why you aimed for vapor barrier in the metal trailer – this is a big No (mold). With all the chemicals used, it's better to just buy older fiberglass/aluminum-frame used trailer which had off-gassed (like Jayco), it'd be better in most cases, costs a lot less and has plumbing. One can take showers or cook just fine in trailers without moisture issues. Cargo trailers don't have the right suspension (shock absorption) to make them durable/resistant to shaking on the road unlike some trailers built for human camping; this is the reason for leaks, not just framing. It'a a very bad idea to seal up insulation/add vapor barrier in metal structure. For chemical free insulation one can buy wool batting off alibaba; there's also hemp option. Main thing not to cover it up with barrier, internal wall surface must breathe and be easily removable by pieces to inspect leaks (be modular). Not sure why you'd want to use, plywood which is toxic, to make your bed. Also, cedar is not good for making a bed (look up; it's outgassing is a strong cancerogen)

Unknown

Thank you so much for this information! I am going to be converting a cargo trailer into a camper/house for my kids and I to travel in. I want to make sure I do things correctly to not have mold issues. I have a tight budget and everything will be done diy. I was wondering about the strength of the trailer without the plywood. This is the only place I could find any information about that. So thank you. I wanted to use pallet wood, since it’s free and hasn’t been made with any kind of glue. I was also thinking to use some kind of natural insulation. I have heard about a wool insulation that is mold resistant and still insulates if it gets wet. We were going to use it in our house but decided to go on the road. Also I’d like to add that I just learned that metal screen blocks out EMFs. That adding chicken wire/ old metal screen in the walls of a house will blocks EMFs. Wonder if that would work? Could use the screen to hold insulation in while also blocking EMFs? So if I were to use the natural insulation and the pallet wood, what should I put between the two? I would also have small holes covered with screening in the bottom under insulation in case of any moisture. Any comments or information would be great!

Corinne

A cargo trailer is a very tricky project. I would not use natural or permeable insulation. I would not use wood in the walls or as the walls in most situations. I did not find that having weep holes was a good idea. If you are heating this trailer you have a very difficult trailer to design. You already have an EMF cage with the exterior shell. Being inside of that and having any electronic devices or electrical appliances inside can be difficult for some people.

JeckRyan

Simply have a bit of ventilation. That will solve some issues. A dry source of heat, and AC are both a real good idea as well.. Our cargo conversion has two screen doors and a few screened windows.Most of the time it is opened up to the fresh air.

Unknown

Thank you for replying. No we will not be heating or cooling the trailer. We will have plenty of windows for ventilation. We will be traveling in it most of the year, so it will be ventilated often. I’ll be reading through all the information on your site and welcome any information you offer. It’s really hard to find this much detail on converting a cargo trailer. Thank you.

Unknown

The only drawbacks of wool insulation are it being expensive (if bought in the US where it's total ripoff) and subject to moths eating it. One can get better pricing buying wool batting off alibaba but with wool one has to make sure what they're getting haven't been doused with naphtalene and doesn't have moths at the same time (so probably best to use natural moth repellent before installing). I prefer camel wool, much better than sheep wool.

Unknown

To Corinne: "I would not use natural or permeable insulation" – this would hold only if one tries to seal it up with vapor barrier (which is a big no in general). Wool insulation is one of the best options for metal trailer; main thing: the internal wall cover must be breathable (I prefer cotton fabric for it, no I don't use polyether which is toxic). Wool is anti microbial/anti bacterial and anti fungal. Real wool (raw), with did not have lanolin removed, resists moisture/does not accumulate it. It breathes (unlike toxic foams) and any potential wall condensation will evaporate without causing mold issues. With foam, not only you have toxic chemicals everywhere you also have accumulation of condensation or leak water on the inner side of outer walls.