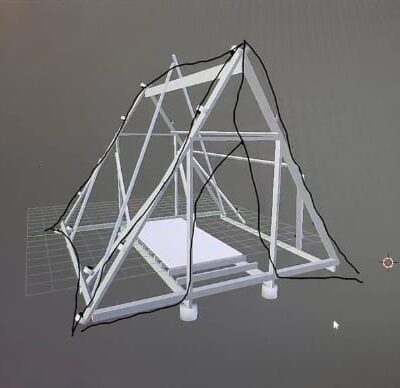

Simple Insulated Shelter for Chemical Sensitivity (MCS) and Mold Avoidance

This post is about two highly insulated shelters I made with rigid foam, raised off the ground and covered in a tarp. These shelters are super simple, super tolerable for the chemically sensitive and are ideal for mold avoidance in cold weather (or even in hot weather). This has the same insulative value that a house …